Custom Machining & Manufacturing

| |

Machines & Capabilities

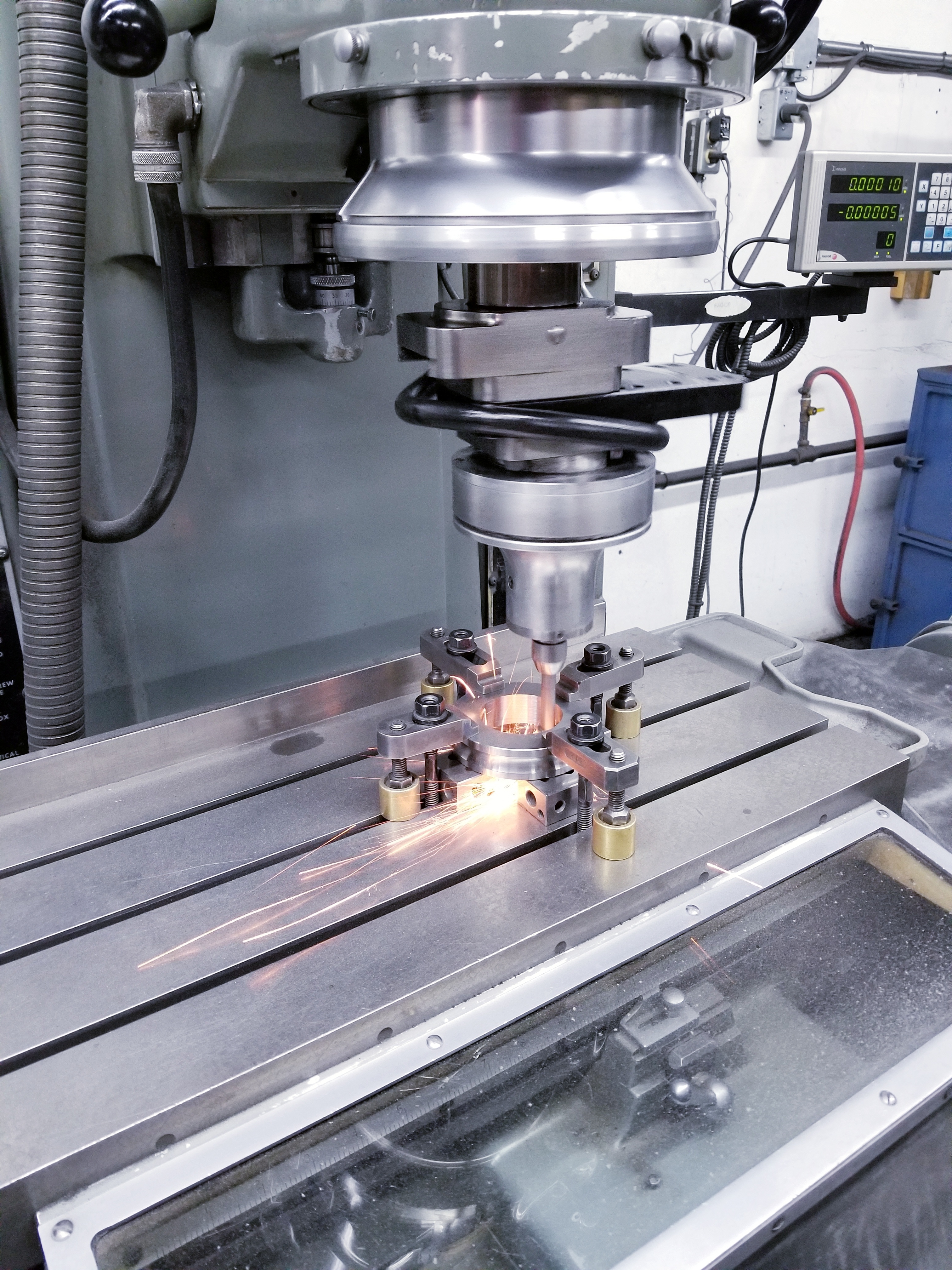

Jig Grinding:

- 3 MOORE #3 G18 with Digital readouts

- Laser Calibrated

- 10" maximum OD

- 1.5mm smallest ID

- Jig Grind tight Tolerances (up to 0.0001")

- Bores with tight tolerances

- Accurate dowel locations

- Bore positional tolerances

- Surface finish

- Utilizing Sunnen Bore Gauges, 0.0001" Pin Gauges, Mitutoyo Digital Mics & Inspection Instruments

Surface Grinding:

- CAMUT 12" x 28"

- CHEVALIER 6" x 10"

- KENT 8" x 14"

- Surface Grind tight Tolerances (up to 0.0001")

- Surface Finish

- Flatness/ Parallelism

- High Tolerance sizing/ squaring

CNC Lathe:

- HAAS HL-4

- Maximum cutting Diameter: 14.5"

- Maximum Cutting Length: 34"

- Distance between centers: 39", 10" 3 Jaw Hydraulic power Chuck @ 3400rpm

CNC Vertical Mill:

- HAAS VF4 - 60" x 20" @ 15,000rpm, 4th axis ready at 30 degrees

- HAAS VF3 - 48" x 20" @ 8000rpm, 3 axis

- Machining of Soft and Hardened Steels, Aluminum, Inconel, Garolite, Plastic...

Manual Machines:

- 2 Bridgeport Milling Machines

- 1 Lathe and Various Saws